Pioneering autonomous drones speeding up agricultural science

Remote technology increases productivity for scientists and accelerates solutions for farmers’ fields.

Pasquale D'Andrea used to spend entire mornings at Syngenta's innovation center in southern Italy preparing drones, conducting flights in the field, and uploading data. The field scientist would repeat this three-hour process for each flight throughout the growing season.

"We were taking snapshots at arbitrary moments, potentially missing critical windows when our products show their effects," says D'Andrea. With each flight taking up hours of his time, D’Andrea had little time left for the data analysis that drives scientific understanding.

On-site experimental biostimulant trials in Perugia, Italy. Left to right: Site manager, Michele Cascavilla with Field Scientists Pasquale D'Andrea and Andrea Minelli.

On-site experimental biostimulant trials in Perugia, Italy. Left to right: Site manager, Michele Cascavilla with Field Scientists Pasquale D'Andrea and Andrea Minelli.

Now, he receives notifications on his phone when new crop imagery is ready for analysis. Compact drones, equipped with multispectral cameras and weighing significantly less than previous research models, fly autonomously over trial plots while D'Andrea works in the laboratory or analyzes data at his computer.

The innovation at Foggia research facility represents an evolution in agricultural research methodology. By removing the time burden of data collection, Syngenta is investing in its scientists' ability to develop the deep product knowledge that will drive the next generation of innovative solutions for farmers.

Research game-changer

The change came in October 2025, when Italian aviation authorities approved beyond visual line of sight (BVLOS) operations at the Foggia facility, a first for European agriculture. This regulatory milestone means drones can now operate autonomously while scientists work in laboratories preparing samples, analyzing data at their computers, or conducting field assessments based on insights the drones have already provided.

"Our field scientists are transitioning from being operators to being scientists again," explains James Marshall-Roberts, Digital Lead for Crop Protection Development, Europe. "They're not standing in fields watching drones anymore. They're building understanding, developing insights, and growing our knowledge of how biological products work."

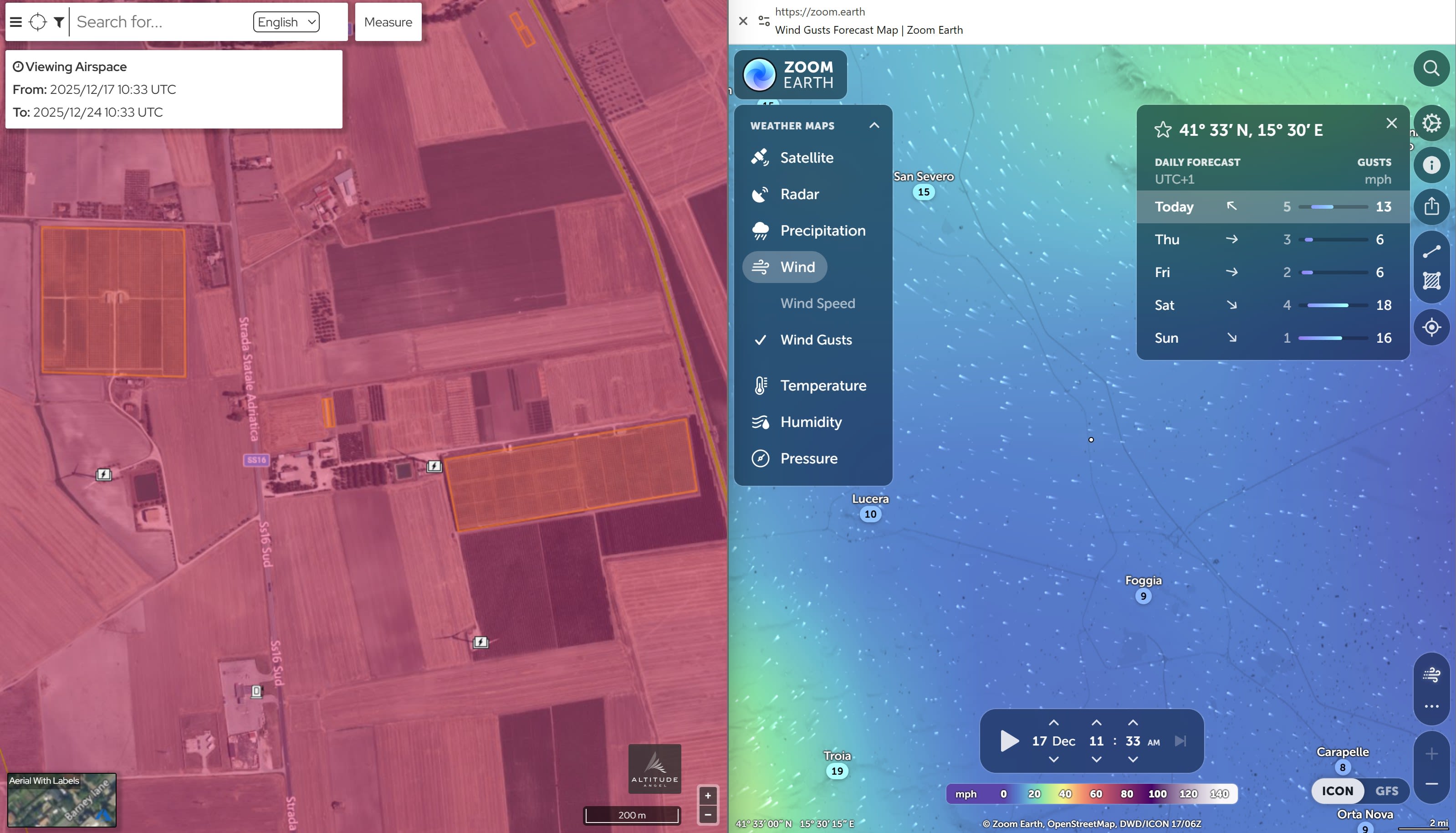

The system operates through an autonomous drone station developed by UK-based company Drone Ag. The station houses the drone, manages flights, and handles data transmission, all coordinated remotely by professional pilots in northern England who monitor weather conditions, camera feeds, and flight parameters in real-time.

James Marshall-Roberts, Syngenta's Digital Lead for Crop Protection Development, Europe.

James Marshall-Roberts, Syngenta's Digital Lead for Crop Protection Development, Europe.

Seeing what the human eye cannot

The technology's real power lies in its ability to detect subtle changes in crop health that are invisible to the human eye.

Using multispectral cameras, the drones capture data across different light wavelengths, revealing how biologicals affect plant vigor, stress responses, and overall health. The high-resolution imagery, capturing details smaller than a millimeter, enables advanced analytical capabilities with precision.

"We're looking at discrete differences in vegetative indices that help us understand how these products are working," says Marshall-Roberts. "Previously, we could only fly two or three times per season due to resource constraints. Now we can fly multiple times per week, tracking how product effectiveness changes over time."

This increased flight frequency, enabled by lower operational costs per flight, opens new research possibilities. Without autonomous operations, this increase would have consumed an additional 12-15 hours of field scientists’ time weekly. Instead, they can focus on analyzing data.

“We can now observe the complete trajectory of product performance, from initial application through the full growing season, rather than capturing isolated snapshots,” says D’Andrea.

Gabriele Gherardi, a member of Syngenta's Digital Europe Team and expert in New Technologies, providing training for drone pilots with a precision agriculture research drone.

Gabriele Gherardi, a member of Syngenta's Digital Europe Team and expert in New Technologies, providing training for drone pilots with a precision agriculture research drone.

Data that drives discovery

After landing, flight data is transmitted via Starlink satellites to cloud-based analysis platforms. The imagery undergoes processing to generate plot-by-plot health indices, which are then integrated into Syngenta's secure platform.

The detailed imagery captures close-up views of plant material, but there is no identifying information about plant treatments. Scientists then match the images with plot boundaries and input protocols to gain deeper insights. This integration enables them to understand precisely what’s happening in each plot and connect those observations to specific products and practices.

"The images show us whether a plot is healthier or under stress," explains Gabriele Gherardi, member of the Digital Europe Team and expert in New Technologies.

"When we combine that visual data with our knowledge of what treatments were applied to which plots, we can build a complete picture of how our products are performing and develop a deeper understanding of their effects," he says.

Enhanced safety and efficiency

Safety protocols are paramount. A team member must be present at the Italian site during operations, positioned near an emergency stop button that can immediately terminate flights if needed. However, that person can work productively on other tasks rather than actively monitoring the drone.

The system includes multiple safety features: weather monitoring equipment on the autonomous station, real-time camera surveillance of the launch area, and communication protocols with site teams to ensure there are no conflicts with other activities.

Enhanced safety and efficiency

Safety protocols are paramount. A team member must be present at the Italian site during operations, positioned near an emergency stop button that can immediately terminate flights if needed. However, that person can work productively on other tasks rather than actively monitoring the drone.

After landing, flight data is transmitted via Starlink satellites to cloud-based analysis platforms.

After landing, flight data is transmitted via Starlink satellites to cloud-based analysis platforms.

The system includes multiple safety features: weather monitoring equipment on the autonomous station, real-time camera surveillance of the launch area, and communication protocols with site teams to ensure there are no conflicts with other activities.

Expanding horizons

The success in Foggia is already catalyzing expansion. Similar systems are being deployed at sites in France near Toulouse, Switzerland near Zurich, and in the UK near Bradford for turf research. Each installation will follow the same remote operation model, building a network of continuously monitored research facilities across Europe.

For D'Andrea at the Foggia site, the technology has been transformative despite initial challenges.

The team (from right to left): Cascavilla Michele, Palmieri Nicola, Di Bianco Domenico, Gherardi Gabriele, D'Andrea Pasquale Pio, Derrico Michele, Piscicelli Marco, Villasanti Federico, Marshall-Roberts James.

The team (from right to left): Cascavilla Michele, Palmieri Nicola, Di Bianco Domenico, Gherardi Gabriele, D'Andrea Pasquale Pio, Derrico Michele, Piscicelli Marco, Villasanti Federico, Marshall-Roberts James.

"The transition wasn't without hurdles - we faced connectivity issues and had to fine-tune the integration with our existing workflows in the first year," says D'Andrea. "But the difference now is striking. I can focus on what the data is telling us. This is what I was trained for.”

"We need that agronomic story," says Marshall-Roberts. "We need to understand these products deeply so we can demonstrate their value to farmers. This technology gives our scientists the time to build that knowledge."