The science and success of biologicals in agriculture

How Syngenta is at the cutting-edge of the fastest-growing market in agriculture

On his family farm in Italy, Marco La Selva looks over vines that have weathered generations of harvests. The land carries the weight of family heritage, but today it faces unprecedented challenges.

“We've noticed areas that used to be green are now dry and weather patterns change more frequently. Every season has presented peculiar differences,” he says.

Marco La Selva reflects on the agricultural challenges his farm faces.

Marco La Selva reflects on the agricultural challenges his farm faces.

Like many farmers around the world, La Selva must manage increasing water scarcity. So, to get the most out of the available water supply he’s introduced biological products that help crops use water more efficiently. Not only does this have a beneficial environmental impact, but it saves money too.

La Selva's experience mirrors a global shift. Over the past decade, biologicals have evolved from niche alternatives to essential tools in farmers' arsenals, addressing everything from pest control to nutrient efficiency. The market for biologicals is projected to exceed USD $20 billion by 2030.

This year, Syngenta is celebrating its 25th anniversary. Check out more of our stories about innovation.

This year, Syngenta is celebrating its 25th anniversary. Check out more of our stories about innovation.

On his family farm in Italy, Marco La Selva looks over vines that have weathered generations of harvests. The land carries the weight of family heritage, but today it faces unprecedented challenges.

“We've noticed areas that used to be green are now dry and weather patterns change more frequently. Every season has presented peculiar differences,” he says.

Marco La Selva reflects on the agricultural challenges his farm faces.

Marco La Selva reflects on the agricultural challenges his farm faces.

Like many farmers around the world, La Selva must manage increasing water scarcity. So, to get the most out of the available water supply he’s introduced biological products that help crops use water more efficiently. Not only does this have a beneficial environmental impact, but it saves money too.

La Selva's experience mirrors a global shift. Over the past decade, biologicals have evolved from niche alternatives to essential tools in farmers' arsenals, addressing everything from pest control to nutrient efficiency. The market for biologicals is projected to exceed USD $20 billion by 2030.

This year, Syngenta is celebrating its 25th anniversary.

This year, Syngenta is celebrating its 25th anniversary.

Types of biologicals

Generally, biologicals fall into three distinct categories.

Biocontrols help farmers manage pests and crop threats through products based on naturally-occurring materials. Biostimulants — currently the largest market segment — enhance plant performance and stress tolerance, enabling crops to withstand stresses such as temperature fluctuations and water scarcity. Finally, nutrient use efficiency (NUE) biologicals optimize plants' absorption and use of essential elements like phosphorus, nitrogen and potassium.

Within these three categories there are different product types – each with their own strengths and challenges. Biologicals can range from pheromone-based pest control to plant extracts or metabolites, to naturally occurring microbes or unique designed proteins.

Types of biologicals

Generally, biologicals fall into three distinct categories.

Biocontrols help farmers manage pests and crop threats through products based on naturally-occurring materials. Biostimulants — currently the largest market segment — enhance plant performance and stress tolerance, enabling crops to withstand stresses such as temperature fluctuations and water scarcity. Finally, nutrient use efficiency (NUE) biologicals optimize plants' absorption and use of essential elements like phosphorus, nitrogen and potassium.

Within these three categories there are different product types – each with their own strengths and challenges. Biologicals can range from pheromone-based pest control to plant extracts or metabolites, to naturally occurring microbes or unique designed proteins.

Market developments

Jérôme Cassayre, Head of Research for Biologicals at Syngenta, characterizes the current moment as transformative. "Biologicals represent the fastest-growing sector in crop protection," he notes, "driven by regulatory changes, consumer demand, and growing farmer interest worldwide."

This demand has sparked an entrepreneurial gold rush, with numerous start-ups entering the field. Yet Cassayre identifies a critical gap: "There's massive demand and excitement, but an innovation deficit we're working to close."

Jérôme Cassayre, Head of Biologicals Research, Syngenta.

Jérôme Cassayre, Head of Biologicals Research, Syngenta.

Cassayre explains things like this: “There's the first level of innovation – when the benefits are clear, but there are challenges to overcome. This can include things like improving the efficacy, the convenience, and with microorganisms, boosting the stability.”

But Cassayre is also hugely optimistic about how the science is already advancing. “We’re reaching level two, where we boost efficacy and performance, making biologicals an ever more reliable technology. Ultimately, we want to hit level three – with biologicals as a consistent complement to conventional chemical options.”

Scientific challenges

Achieving this vision requires overcoming some complex scientific hurdles.

Cassayre identifies two primary challenge categories, beginning with technical obstacles: "How do we scale biomanufacturing cost-effectively while maintaining quality?"

The living nature of biologicals complicates production. "Microorganisms are delicate," Cassayre explains. "We must build partnerships and scale fermentation carefully."

Beyond production lies formulation — biologicals are inherently less stable than conventional chemistry, requiring sophisticated slow-release and precision application technologies.

The second challenge involves research strategy. "We don't just want discovery," Cassayre emphasizes. "We need to bring to farmers a clear understanding of how our biological products work." This knowledge transfer is crucial for proper application and use, creating what he calls "a virtuous circle of trust and innovation between scientists and farmers."

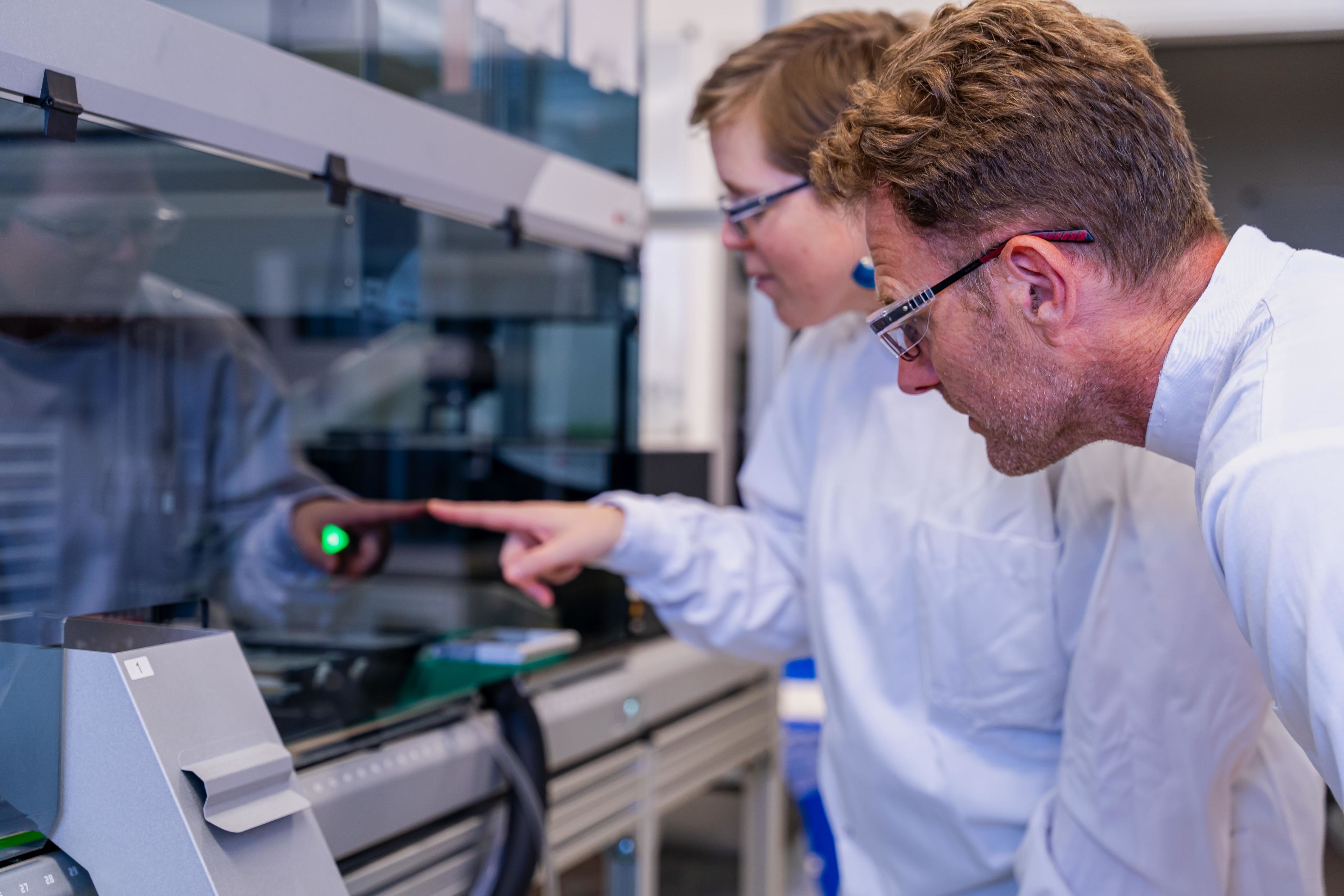

The development of effective biological solutions requires significant scientific expertise. At Syngenta, advanced research platforms such as GeaPower® are used to study and develop these natural compounds. This involves understanding the complex interactions between beneficial microorganisms and plants, identifying promising active ingredients, and developing reliable extraction and formulation processes. This infrastructure helps accelerate the discovery and delivery of biological solutions that farmers can trust to perform consistently in their fields.

From discovery to field application

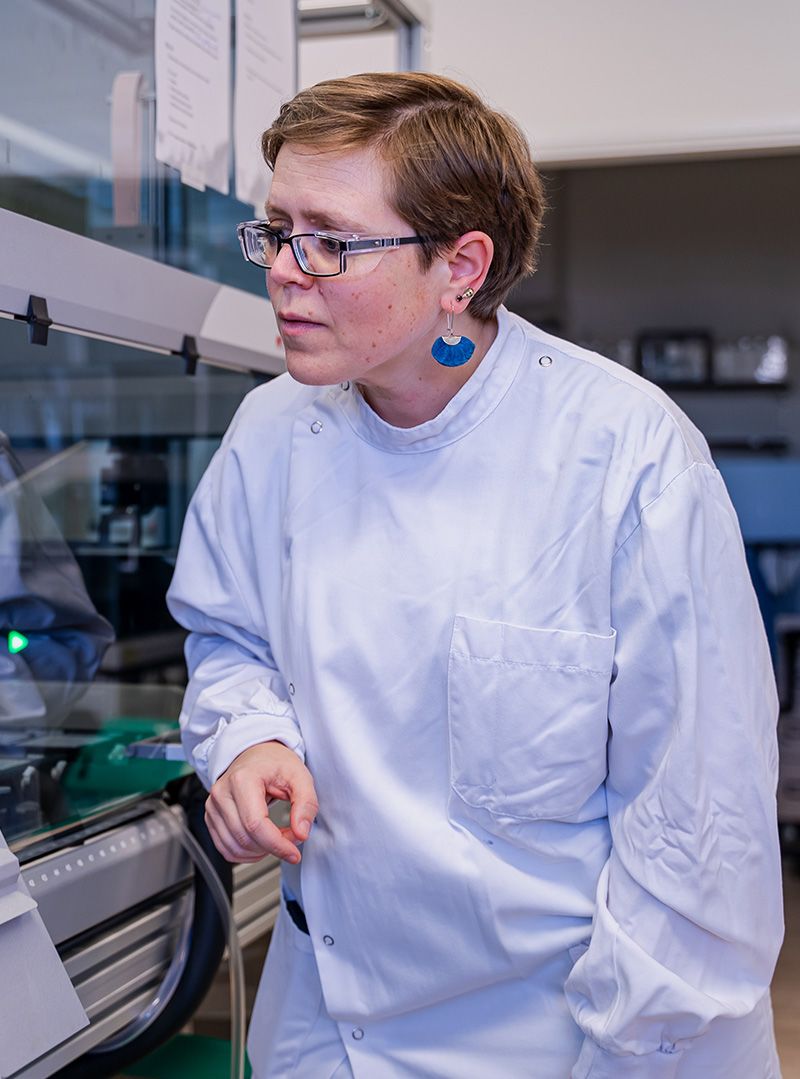

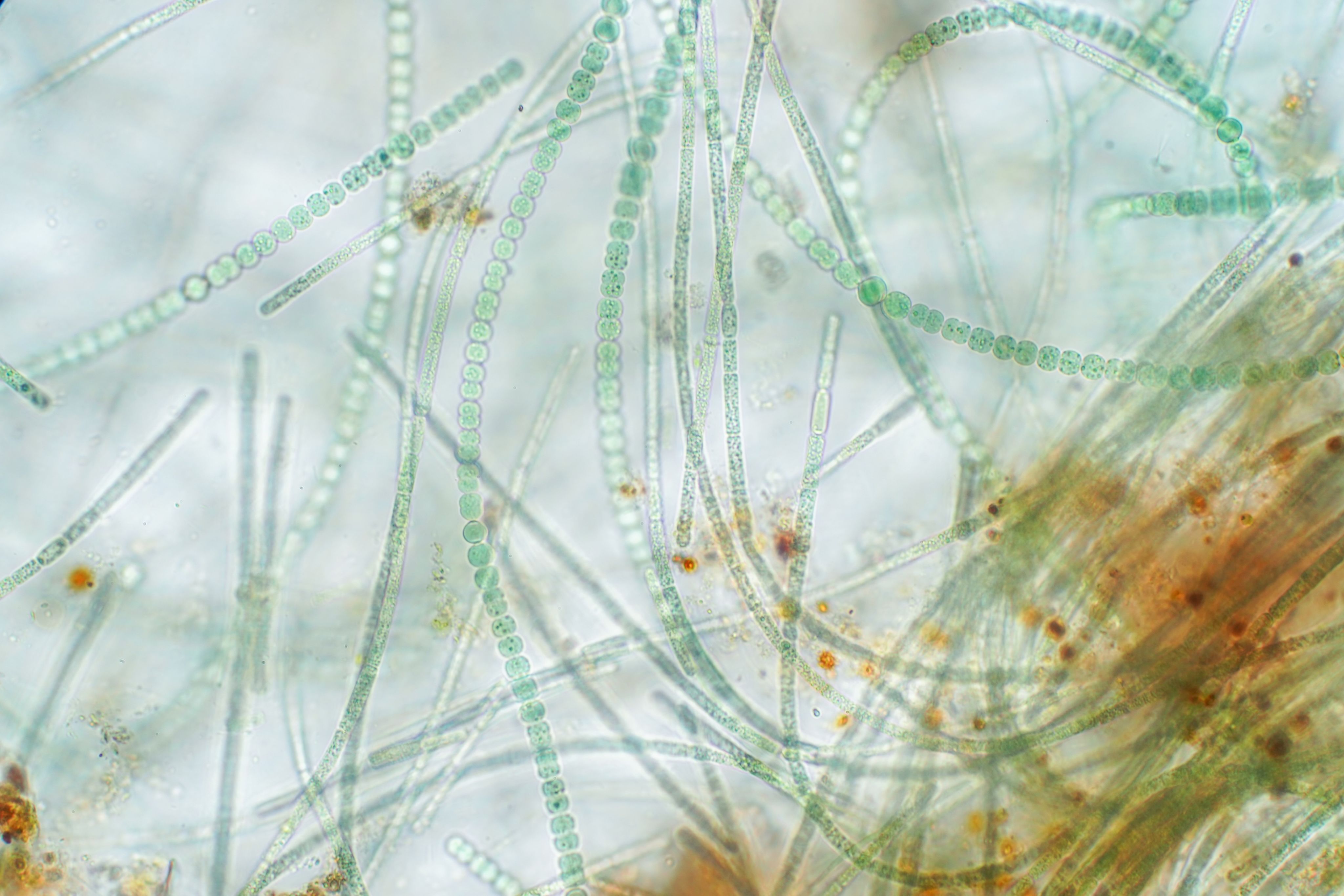

As Emilie Fritsch, Principal Scientist at Syngenta’s Jealott’s Hill Research Center in the UK, points out, discovering new biological products is a complex process. “Biologicals have different functions, but they also come in different forms. These range from microbials, which are live cells or extracts to proteins or synthetic biology. There are also natural extracts derived from things like algae.”

The diversity of different options means that finding promising options means taking a wide approach. Fritsch explains: “Think of it like a funnel - with microbials we might start with testing thousands of live cells or extracts and end up with only a few promising candidates.”

But as biologicals have developed, the search process has become increasingly sophisticated. "We know more about what we're looking for now," Fritsch says, "using genomics and metabolomics to accelerate the process." For proteins and peptides, breakthroughs like AlphaFold have helped speed up development timelines.

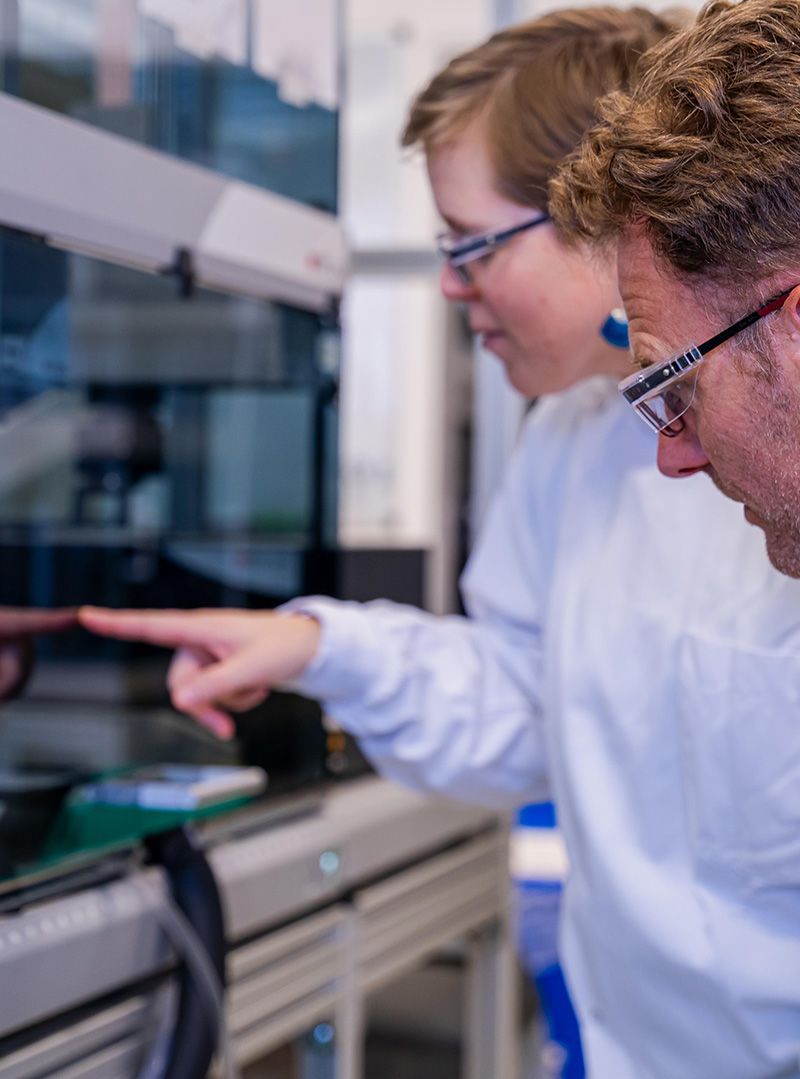

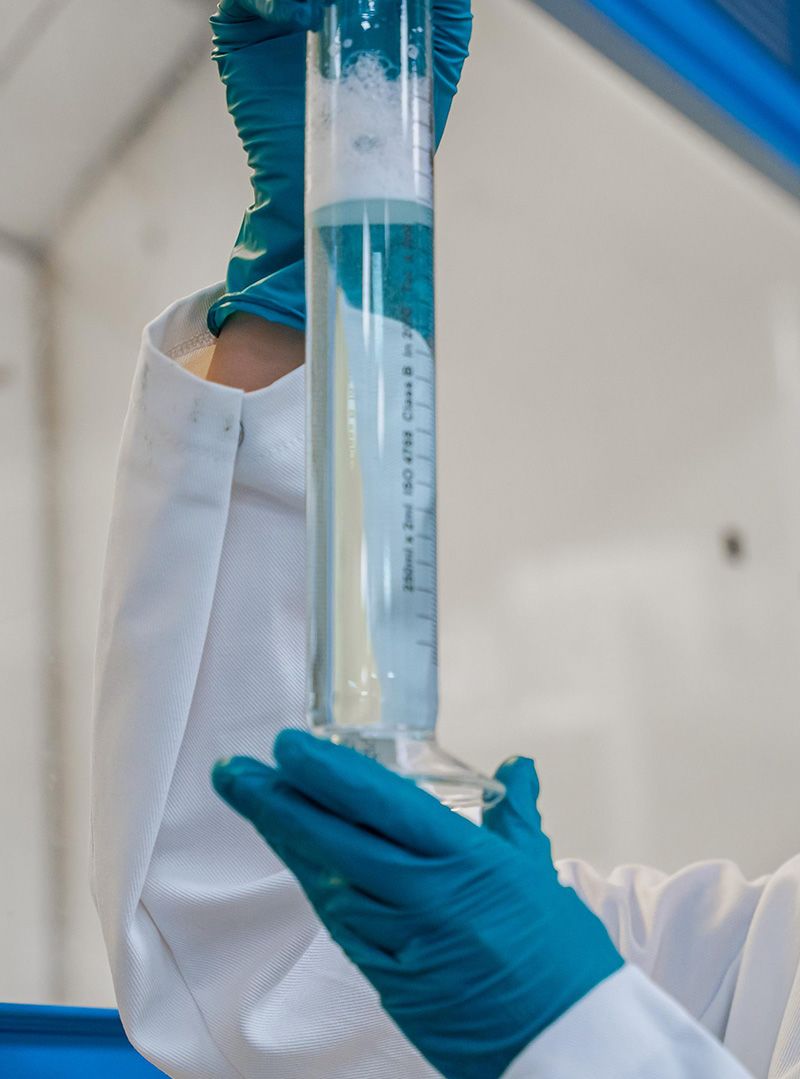

When a promising candidate has been found it’s time to scale up production, but this comes with its own unique challenges. Douglas Hodgson, Bioprocess Development Team Leader, says: "You're dealing with living organisms — more unpredictable and complex than conventional chemistry."

Ensuring a robust, scalable process is critical, requiring advanced microbial technology platforms in the lab and access to both pilot and manufacturing scale fermentation capacity through internal investments and strategic partnerships.

Syngenta's global capabilities in biologicals research, development, and production— spanning England, Switzerland, the United States, and India — enable large-scale testing and collaboration.

This research network matches Syngenta production scale too. The recent opening of a new biologicals manufacturing facility in Orangeburg, South Carolina, will produce 16,000 tons of biostimulants annually, joining facilities in Atessa, Italy, Pirassununga in Brazil and Pashamylaram in India.

Emilie Fritsch, Principal Scientist at Syngenta’s Jealott’s Hill Research Center.

Emilie Fritsch, Principal Scientist at Syngenta’s Jealott’s Hill Research Center.

Syngenta's global capabilities in biologicals enable large-scale testing and collaboration.

Syngenta's global capabilities in biologicals enable large-scale testing and collaboration.

From discovery to field application

As Emilie Fritsch, Principal Scientist at Syngenta’s Jealott’s Hill Research Center in the UK, points out, discovering new biological products is a complex process. “Biologicals have different functions, but they also come in different forms. These range from microbials, which are live cells or extracts to proteins or synthetic biology. There are also natural extracts derived from things like algae.”

The diversity of different options means that finding promising options means taking a wide approach. Fritsch explains: “Think of it like a funnel - with microbials we might start with testing thousands of live cells or extracts and end up with only a few promising candidates.”

But as biologicals have developed, the search process has become increasingly sophisticated. "We know more about what we're looking for now," Fritsch says, "using genomics and metabolomics to accelerate the process." For proteins and peptides, breakthroughs like AlphaFold have helped speed up development timelines.

When a promising candidate has been found it’s time to scale up production, but this comes with its own unique challenges. Douglas Hodgson, Bioprocess Development Team Leader, says: "You're dealing with living organisms — more unpredictable and complex than conventional chemistry."

Ensuring a robust, scalable process is critical, requiring advanced microbial technology platforms in the lab and access to both pilot and manufacturing scale fermentation capacity through internal investments and strategic partnerships.

Syngenta's global capabilities in biologicals research, development, and production— spanning England, Switzerland, the United States, and India — enable large-scale testing and collaboration.

This research network matches Syngenta production scale too. The recent opening of a new biologicals manufacturing facility in Orangeburg, South Carolina, will produce 16,000 tons of biostimulants annually, joining facilities in Atessa, Italy, Pirassununga in Brazil and Pashamylaram in India.

Emilie Fritsch, Principal Scientist at Syngenta’s Jealott’s Hill Research Center.

Emilie Fritsch, Principal Scientist at Syngenta’s Jealott’s Hill Research Center.

Syngenta's global capabilities in biologicals enable large-scale testing and collaboration.

Syngenta's global capabilities in biologicals enable large-scale testing and collaboration.

Chemistry challenges

Even biological products require sophisticated analytical chemistry. Dimitrios Papasotiriou, Principal Scientist in Structural Chemistry, explains how biologicals pose a reverse engineering challenge.

“In traditional chemistry you start from a hypothesis and test to see if it works. With biologicals we are often work backward — we know something works or has a particular effect but need to understand how and why.”

Biologicals pose a reverse engineering challenge for scientists.

Biologicals pose a reverse engineering challenge for scientists.

Through extraction methods and analytical techniques like chromatography, mass spectrometry, nuclear magnetic resonance and other techniques, analytical chemists help to break down, identify and characterize the different components of each unique biological product. This understanding enables the refining of production methods leading to more powerful and effective products.

For Papasotiriou, biologicals are an exciting new area: “They’ve really pushed us forward to try and use our technical capabilities at a new level. We’re using technologies like genomics, metabolomics and proteomics to really understand how chemicals, proteins and metabolic pathways interact.”

Rosa Dominguez-Espinosa, Syngenta Fellow

Rosa Dominguez-Espinosa, Syngenta Fellow

Simultaneous solutions

Rosa Dominguez-Espinosa, Syngenta Fellow for Biologicals Formulation, helps tackle another of the field’s complex challenges: transforming biological discoveries into farmer-ready products.

Given the complexity of biologicals, formulation experts are usually involved earlier than they would be in conventional chemistry.

Dominguez-Espinosa says: “The diversity of biological active ingredients means that formulation has to solve multiple challenges simultaneously.” Formulations must ensure stability and shelf life regardless of storage conditions, prevent contamination, and maintain compatibility with active ingredients.

Consider Nutrient Use Efficiency (NUE) products. These face complex challenges beyond simply boosting nutrient efficiency. Each product must effectively deliver nutrients to the right place within the plant and maintain the desired level of activity.

Dominguez-Espinosa recalls working with a biological active ingredient combining vegetative cells, fermentation broth, and low-concentration metabolites that lost efficacy in water suspension. The team faced the challenge of maintaining a high-volume of this complex biological active ingredient while having minimal space for co-formulants in the final product.

After testing several options, Syngenta’s formulation experts developed water-free liquid formulations that can help keep the active cells viable and have a low risk of microbial contamination. Each project’s formulation is carefully and meticulously tested to ensure ease of use and to boost the efficacy and reliability of these essential new tools.

Rosa Dominguez-Espinosa, Syngenta Fellow.

Rosa Dominguez-Espinosa, Syngenta Fellow.

Each project’s formulation is meticulously tested to ensure ease of use and to boost the efficacy and reliability.

Each project’s formulation is meticulously tested to ensure ease of use and to boost the efficacy and reliability.

Simultaneous solutions

Rosa Dominguez-Espinosa, Syngenta Fellow for Biologicals Formulation, helps tackle another of the field’s complex challenges: transforming biological discoveries into farmer-ready products.

Given the complexity of biologicals, formulation experts are usually involved earlier than they would be in conventional chemistry.

Dominguez-Espinosa says: “The diversity of biological active ingredients means that formulation has to solve multiple challenges simultaneously.” Formulations must ensure stability and shelf life regardless of storage conditions, prevent contamination, and maintain compatibility with active ingredients.

Consider Nutrient Use Efficiency (NUE) products. These face complex challenges beyond simply boosting nutrient efficiency. Each product must effectively deliver nutrients to the right place within the plant and maintain the desired level of activity.

Dominguez-Espinosa recalls working with a biological active ingredient combining vegetative cells, fermentation broth, and low-concentration metabolites that lost efficacy in water suspension. The team faced the challenge of maintaining a high-volume of this complex biological active ingredient while having minimal space for co-formulants in the final product.

After testing several options, Syngenta’s formulation experts developed water-free liquid formulations that can help keep the active cells viable and have a low risk of microbial contamination. Each project’s formulation is carefully and meticulously tested to ensure ease of use and to boost the efficacy and reliability of these essential new tools.

The future of farming

Regulatory frameworks for biologicals remain inconsistent globally, creating additional complexity for scientists and companies. Despite these challenges, the scientific community's enthusiasm remains undimmed.

“The diversity of scientists involved is so exciting,” says Cassayre. “The scale of our operation is useful but in biologicals we also need to rely on external partnerships with other companies and research institutions, so we need to be close to these people and leverage the local ecosystems.”

With the agriculture systems of the world facing seismic challenges, and farmers everywhere needing to produce more food with fewer inputs, this kind of collaborative science isn’t just exciting – it’s essential.

A solution from the sea...

One of the most popular ingredients used in biologicals today is seaweed. Ascophyllum Nodosum, a large brown algae, grows in the cold water of the North Atlantic and is a common site across the arctic coasts of Norway.

Extracts derived from this algae are enormously powerful. Through careful extraction and formulation processes, A. Nodosum can help plants cope with changing climate, maximize their use of resources and reach their yield potential.

Responsibly managed and sustainably harvested, this seaweed extract can help ensure crops are more resilient, meaning more security for farmers and their harvests.

Find out how Syngenta is helping unlock the potential of seaweed for farmers everywhere.

This year, Syngenta is celebrating its 25th anniversary. We are proud of our continuous innovation and contribution to the food system over the past quarter century. Check out more of our stories about innovation.

This year, Syngenta is celebrating its 25th anniversary. We are proud of our continuous innovation and contribution to the food system over the past quarter century. Check out more of our stories about innovation.